How to Set Up Your Rotary Hoe

>

>Mounting the Machine to the Tractor

The machine must be attached to the tractor using the three-point hitch system with the provided pins. After mounting, the hydraulic system should also be connected. The lower arms of the three-point linkage should not be fully fixed, as the machine requires a small amount of movement. The top adjustable arm should be set to ensure that the machine remains level during work, both lengthwise and crosswise.

For orchard machines, crosswise leveling can also be fine-tuned by adjusting the height of the side support wheel. We additionally recommend mounting the machine on the front of the tractor if a three-point hitch is available there. This makes maneuvering between trees easier, gives the operator more confidence, and allows for higher working speed and overall hectare performance.

>

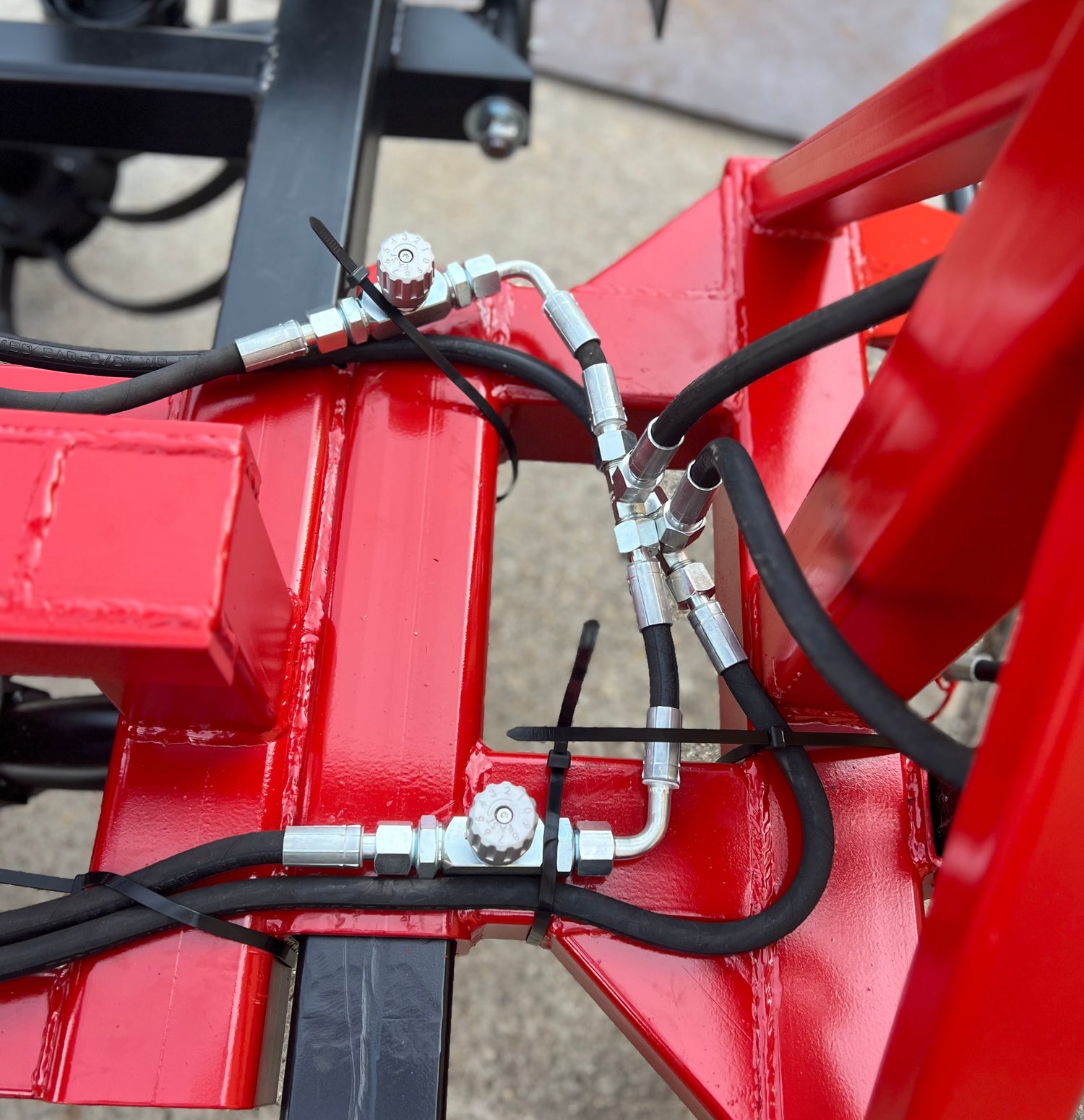

>Initial Setup of the Hydraulic System

For machines equipped with hydraulic width adjustment, hydraulic control valve(s) are provided. During the initial setup, these control valves should be completely closed. We recommend then opening them by about one and a half turns. The goal is to achieve a slow but steady hydraulic width adjustment.

If the machine is equipped with dual-side hydraulic width adjustment and the two sides do not extend at the same speed, the control valve on the slower side should be opened slightly further until both sides operate at the same speed.

>

>Horizontal Adjustment of the Side Rotary Hoes

For both vineyard and orchard machines, setup begins at the start of the row: the tractor should be positioned in the center of the row, and the machine placed in its working position. The working width must be adjusted so that the outer rotary hoe just touches the vine or tree trunk (exception: see Trial Run at the bottom of the page).

To achieve correct alignment, the spring support bracket should be set perpendicular to the direction of travel. This is done by using the middle hole(s) on the horizontal plate located behind the spring support.

Vineyard Machines

- The total working width must match the vineyard row spacing, but it should not exceed it.

- During the first cultivation, when soil ridges need to be broken down, it is advisable to set the working width narrower, typically about 2 × 100 mm less than the row spacing.

- Hydraulic width adjustment allows extension by approx. 200–300 mm on each side (total hydraulic adjustment: 400–600 mm).

- Extra manual width adjustment provides an additional 2 × 80 mm (two manual positions on each side). On request, machines can be custom-manufactured with a wider range of manual adjustment.

Orchard Machines

- Orchard models are typically one-sided.

- They feature a +500 mm side adjustment, with the option for custom extensions if required.

>

>Vertical Adjustment of the Side Rotary Hoe

Regarding the vertical flat bar holding the side rotary hoe:

- The lower holes (flatter setting, typically for looser soils such as sand) should be prioritized whenever possible, depending on soil firmness. This setting ensures better lateral movement of the rotary hoe head, thereby helping to avoid the root zone. However, it is also important that the rotary hoe penetrates the soil properly, which can only be achieved by operating the rotary hoe head at a slightly steeper angle.

- The middle holes (normal setting) are recommended for general use. In this position, the rotary hoe head penetrates the soil effectively, while maintaining adequate lateral movement, ensuring efficient avoidance of the root zone.

- The upper holes (extremely steep setting for more effective "bite" into harder soil) should only be used when the goal is to break down the uncultivated ridge between vineyard/orchard rows. In this case, the machine width should be adjusted to be 2x100 mm narrower than the row spacing (see: "Horizontal Adjustment of the Side Rotary Hoes").

WARNING: If the angle of the rotary hoe head is too flat, it may not rotate properly in proportion to the forward speed. This is undesirable, and in such cases, the steepness of the rotary hoe should be increased. However, an excessively steep setting is less effective in avoiding the root zone, so extreme tilt angles should be avoided.

>

>Towing Speed

For both vineyard and orchard machines, the recommended towing speed depends on soil conditions:

- On compacted soil, a higher working speed can be achieved, up to 10-12 km/h.

- On sandy or loose soil, a recommended speed of 6-8 km/h should be maintained.

In vineyards, the best results are achieved by going back and forth within the same row. This not only loosens the soil and flattens the ground but also allows the machine to operate at even higher speeds compared to the first pass.

In orchards, where the machines are one-sided, work can only be performed in one direction. However, making two passes in the same row delivers the best results for soil loosening and surface leveling.

>

>Trial Run

- We recommend conducting an initial trial run before starting regular work. During this first pass, the outer rotary hoe should not be set to touch the vine or tree trunk. Instead, adjust the working width to be about 100 mm narrower than the row spacing. This helps to break up the uneven surface and allows the operator to gain confidence and experience with the machine.

- Attention: The rotary hoe heads must operate proportionally to the forward speed without "slipping." Perform the trial by lowering the rotary hoe heads into the soil approximately 50-60 cm before the row. Ensure the adjustment angle is sufficient (see: "Vertical Adjustment of the Side Rotary Hoe" above) and that the rotary hoe heads penetrate the soil to a depth of about 100mm. This ensures the rotary hoe heads will effectively roll off the root zone.

- Safety: If the distance between the rotary hoe blades is insufficient to clear the root zone or if the hoe encounters a pole, the side rotary hoe will deflect against the horizontal spring. Once the obstacle is cleared, it will return to its row cultivation position. This deflection movement has a maximum range of 200 mm per side rotary hoe.

Rotary Hoes for Vineyards

-

Vineyard - Basic Single Rotary Hoe (I.)

Regular price €2.190,00Regular priceUnit price / per -

Vineyard - Basic Single Rotary Hoe (II.)

Regular price €2.390,00Regular priceUnit price / per -

Vineyard - Basic Single Front Rotary Hoe (II.fr)

Regular price €2.490,00Regular priceUnit price / per -

Vineyard - Basic Dual Rotary Hoe (1.80-2.20m)

Regular price €3.490,00Regular priceUnit price / per

Rotary Hoes for Orchards

-

Orchard - Basic Single Rotary Hoe (2)

Regular price €3.790,00Regular priceUnit price / per -

Orchard - Pro Single Rotary Hoe (3)

Regular price €4.390,00Regular priceUnit price / per